Vibration Test Fixtures

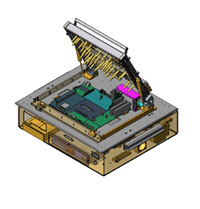

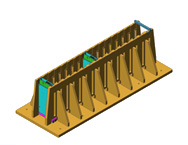

Chassis level Vibration Test Fixture

|

Enclosure level Vibration Test Fixture

|

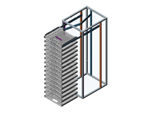

Reliability Test Fixtures

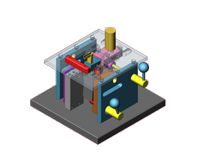

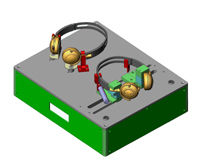

Reliability Test Fixture

|

Reliability Test Fixture

|

RF Chamber Fixture

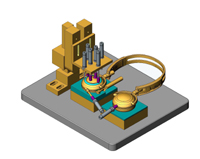

RF Chamber Fixture

|

RF Calibration

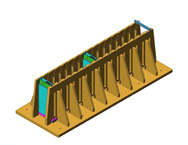

RF Calibration Fixture

|

RF Module Calibration Fixture with Hot and Cold Plate

|

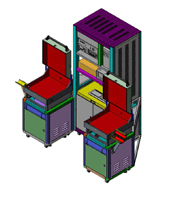

Burn-in Fixture

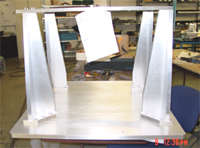

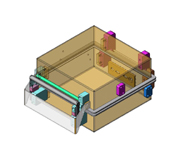

Bench top Chamber

|

BCart Type

|

||||||

Drawer Type

|

IST Engineering Standard Chamber

|

Burn-in Fixture

Burn-in generally involves the extended operation of a product in a temperature-controlled environment. With possible humidity and supply voltage margining - the burn-in process can then be extended to include power stress (levels and on/off cycles) tests, high humidity environmental simulation as well as the classic "four corner test" of high voltage + high temperature, high voltage + low temperature, low voltage + high temperature and low voltage + low temperature.

IST Engineering has the solid experience and the combination of mechatronic and electro-mechanical skills needed to deliver the needed functionality on time. Our products are designed internally, and integrate power supplies, our own power supply controllers ("voltage margining unit or wiggler"), high amperage, and high temperature wiring with fans with heating elements.

IST Engineering can provide own off the shelf burn-in chamber or design and build custom chamber for your application.

IST Engineering will design, fabricate, integrate, validate and deliver these systems to you.